- Elektrowerkzeuge

-

Sägen

Kettensäge Betonkettensäge Säbelsäge Bandsäge ...

-

Bohrer

Schlagbohrer Handbohrer Leichter Bohrer Gleichgewichtsübung ...

-

Mühlen

Pneumatischer Wasserzerkleinerer Pneumatischer Winkelschleifer Elektrischer Winkelschleifer

-

Schraubenschlüssel

Schlagschrauber Drehmomentschlüssel Nussläufer

-

Hämmer

Nussbrecher Pneumatische Entrostungsschaufel Pneumatische Meißelhämmer Hydraulischer Meißelhammer ...

-

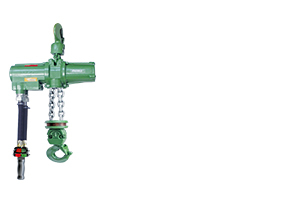

Hubkran

Winde Pneumatischer Hebekran

-

PUMPS

Hydraulische Pumpe Tauchpumpe

-

Andere

Fans Hog-Ring-Zange

-

- Zubehör

-

Bohrer / Meißel

Bohrer aus Legierung Twist-Bit Hülse mit Morsekegelschaft Hohlbohrer ...

-

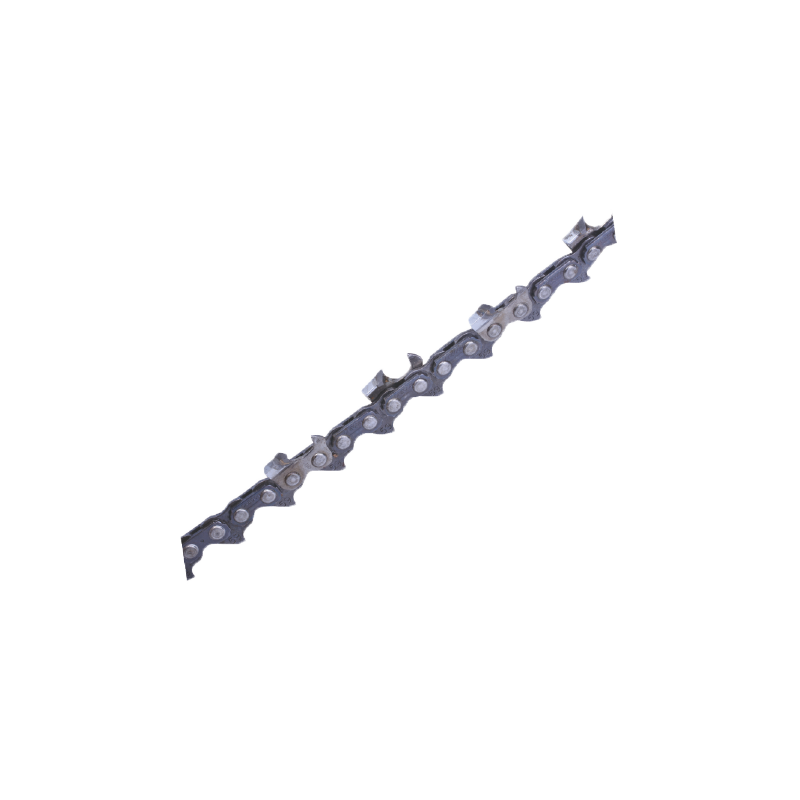

Sägeketten / Führungsschienen

Legierte Führungsstangen Sah Kette Alu-Sägekette Diamantkette ...

-

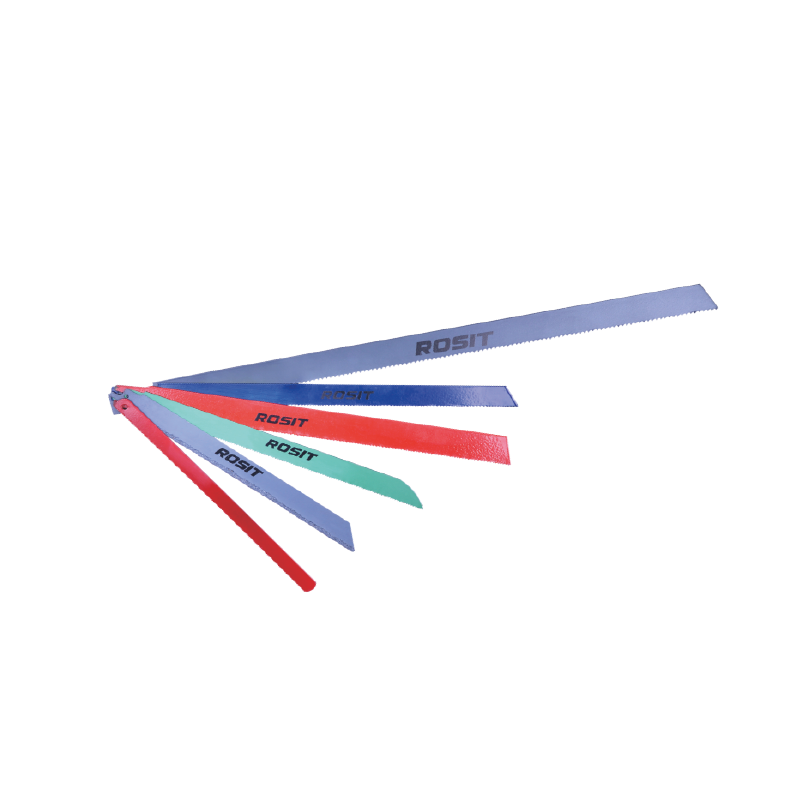

Säbelsägeblätter / Klemmen

Alu-Sägeblatt Vielseitige Klemmen Rohrschelle

-

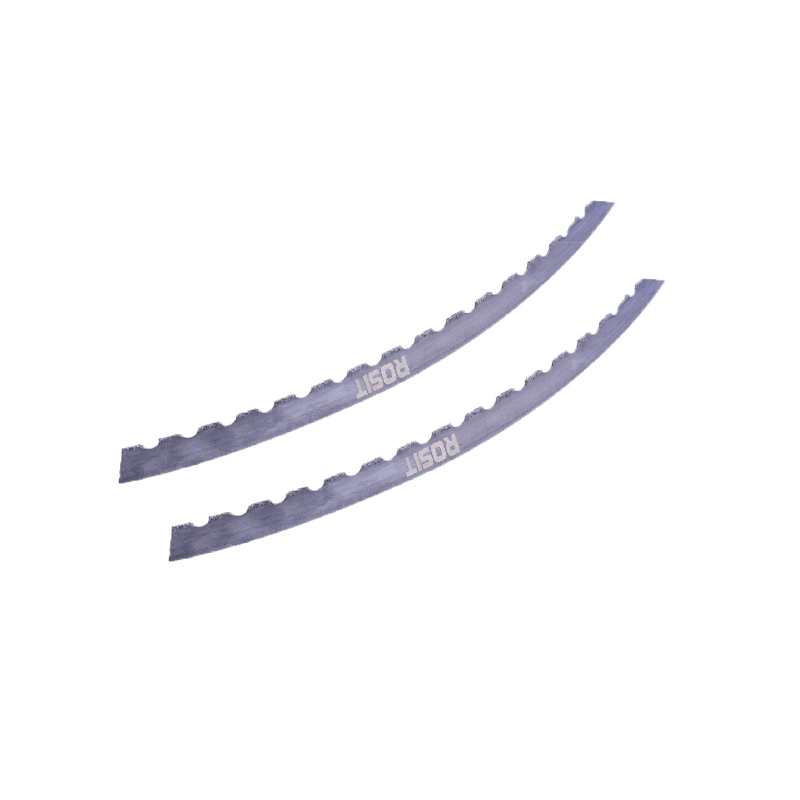

Bandsägeblätter / Klemmen

Sägeblatt aus Legierung Diamant-Sägeblätter Feste Klemmen

-

Kreissägeblätter

Kreissägeblätter aus Legierung Diamantkreissägeblätter Kreissägeblätter aus Karborund

-

Steckdosen

Legierungsbuchsen Sockel-Kits Explosionsgeschützter Steckdosensatz Verlängerungsstange ...

-

Sonstiges Zubehör

Filtermontage Wasserpumpe Öler Hydraulische Pumpstation ...

-

- Firmenprofil

- Geschäftsentwicklung

- Bedienung

- Nachrichten

-

Veranstaltungen

Die 20. TaiYuan (2021) Kohle ( 16. Orden Internationale Kohle Eine Maschine reparieren lasse

-

Neustart

Eine Maschine reparieren lasse

-

Neuigkeiten aus der Branche

Verbessern Sie die Lebensdauer Gemeinsame Klassifizierung und Wartung von hydraulischen Schr Das Prinzip der Reihen- und Pa Auf welche Probleme bei der Re ...

-

- Datei wird heruntergeladen

- Kontakt

Auswahlhilfe für hydraulische Schraubenschlüssel! Unternehmen für Bügelsägen

Quelle:Neuigkeiten aus der Branche Ver?ffentlichkeitsdatum:2021-09-27 Autor des Artikels:Rosit Beliebt:Luftbands?ge

How should hydraulic wrenches be selected? This question (Emerson) must be unknown to many people, so let’s study with the editor of Hydraulics today!

1. Confirmation of torque

Refer to the drawing requirements to find out what the torque value of the bolt (composition: head and screw) is. [If you don’t know what the required bolt torque is, please refer to the "bolt and nut maximum torque recommendation table" according to the size of the bolt (nut) , Strength (strength) grade and material quality] to get the corresponding torque value;

2. Considering the position of space (consider)

Due to many factors (limit) on site, please pay attention to the position of the space used when choosing (xuanze) wrench, such as:

In case of the above working conditions, when the drive type cannot work, you can choose (xuanze) hollow hydraulic wrench. The hydraulic wrench transmits power to the working head through the high-pressure oil pipe and the hydraulic pump, which drives the working head to tighten or loosen the nut. The hydraulic pump can be driven by electricity or compressed air. The working head of the hydraulic wrench is mainly composed of three parts, the frame (also called the shell), the oil cylinder and the transmission parts. The output force of the oil cylinder, the piston rod of the oil cylinder and the transmission part form a motion pair. The distance from the center of the oil cylinder to the center of the transmission component is the hydraulic wrench amplification arm. The oil cylinder output multiplied by the arm is the theoretical output torque of the hydraulic wrench. The actual output torque is smaller than the theoretical output torque. Its unique (interpretation: unique, special) is that the wrench can be divided into two parts: the working head part and the power head part. The power of the same model remains unchanged. Within the working range (fàn wéi) of this model, it can be passed ( tōng guò) Replace the working head to realize the disassembly and assembly of bolts of different specifications (composition: head and screw); in addition, a reducing sleeve can be added to the working head to change the size of the opposite side to realize disassembly and assembly of different specifications The selection of the hollow type hydraulic torque wrench is the same as that of the drive type wrench in principle.

Leseempfehlungen:

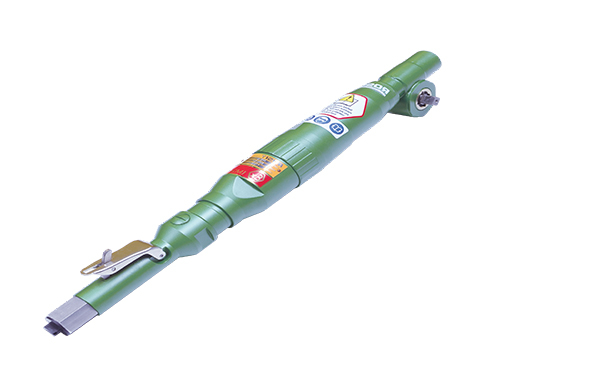

AW21-2000 Pneumatischer Schlagschrauber

Zum Thema passende Artikel

Verbessern Sie die Lebensdauer von manuellen Hydraulikpumpen. Luftschlagschrauber Verarbeitung

2022-02-19Gemeinsame Klassifizierung und Merkmale der hydraulischen Schraubenschlüsselpumpe. Verkauf von Druck

2022-02-18Wartung von hydraulischen Schraubenschlüsseln und Vermietung von hydraulischen Schraubenschlüsseln.

2022-02-17Das Prinzip der Reihen- und Parallelschaltung von Freistrompumpen. Hersteller von Lufthebezeugen

2022-02-16Auf welche Probleme bei der Reparatur der Wirbelluftpumpe geachtet werden sollte. Luftschlagschraube

2022-02-15Beschädigung des O-Rings des Hydraulikschlüssels während der Installation. Preis für Druckluft-Schla

2022-02-14Was sind die häufigsten Fehler von Hydraulikschraubern?

2022-01-28Definition und Eigenschaften des hydraulischen Schraubenschlüssels

2022-01-27So wird die Geschwindigkeit des Hubhubes des Elektro-Hydraulikschraubers von der Durchfluss-Hydrauli

2022-01-26Analyse des Prinzips des hydraulischen Wagenhebers.Luftmotor

2022-01-25Klassifizierungsmerkmale und Qualitätskennzeichnung von Hydraulikschraubern

2022-01-24Die unermessliche zukünftige Entwicklung von hydraulischen Schraubenschlüsseln ist zu einem Branchen

2022-01-21Vorsichtsmaßnahmen für die Verwendung von Hydraulikschraubern

2022-01-20Die Details, die bei der Verwendung von Hydraulikschraubern zu beachten sind

2022-01-19Vorsichtsmaßnahmen für die Verwendung von Hydraulikschraubern

2022-01-17Die hydraulische Technologie hydraulischer Tragen wird in verschiedenen Branchen eingesetzt.Pneumati

2022-01-17Das Arbeitsprinzip des hydraulischen Schraubenschlüssels

2022-01-12Anwendung von hydraulischen Schraubenschlüsseln in der Erdöl- und petrochemischen Industrie

2022-01-06Preis für ultradünnen hohlen Hydraulikschlüssel

2022-01-06Anleitung zur richtigen Verwendung von hydraulischen Wagenhebern

2022-01-05Der Arbeitshohlraum der hydraulischen Mutter und des hydraulischen Schraubenspanners wird nicht mit

2021-12-28Hauptmerkmale des hohlen hydraulischen Drehmomentschlüssels. Fabrik für pneumatische Schlagschrauber

2021-12-25Wie man hydraulische Schraubenschlüssel verwendet und auf Probleme achtet. Hydraulische Drehmomentsc

2021-12-25Was sind die Vorbereitungen für hydraulische Drehmomentschlüssel vor dem Einsatz?

2021-12-24Auf welche Probleme ist im täglichen Einsatz von Hydraulikschraubern zu achten

2021-12-24Installation und Vorsichtsmaßnahmen der Luftpumpe für hydraulische Schraubenschlüssel

2021-12-23So lösen Sie die hohe Temperatur des Hydraulikschlüssels

2021-12-23Einfache Wartungsschritte des hydraulischen Schraubenschlüssels nach dem Betrieb

2021-12-22Wie oft wechselt ein Hydraulikschrauber das Hydrauliköl?

2021-12-22Einfache Wartungsschritte des hydraulischen Schraubenschlüssels nach dem Betrieb. Firma für pneumati

2021-12-21Elektrowerkzeuge

CS31-300 Hydraulische Handkreissäge

2021-06-15AW22-750 Pneumatischer Schlagschrauber (Super Light Serie)

2020-12-07AN32-2500/5000/10000/17000/23000/40000 Hydraulischer Hohlschlüssel

2020-06-13DM11-013~032 Elektrischer Magnetbohrer

2020-06-13Tragbarer Ventilator OF22-500/880 (Edelstahl + Alaunlegierung)

2021-05-17CR21-012 Schwere pneumatische Säbelsäge

2021-06-07CR21-003 Leichte pneumatische Säbelsäge

2021-06-07RH21-3500 Pneumatischer Brechhammer

2021-06-15RC21-1100/1200/1500/1800 Langer pneumatischer Hand-Entrostungsschaufel

2020-06-13DP21-140 Pneumatischer Handbohrer

2021-06-15DL21-008 Pneumatischer Leichtbohrer

2021-06-10DP21-080/100 Pneumatischer Handbohrer

2021-06-15CR21-008 Leichte pneumatische Säbelsäge

2020-06-13CR31-015 Hydraulische Säbelsäge

2021-05-10AW41-3500 Emulsions-Schlagschrauber

2021-06-15DP21-060 Pneumatischer Handbohrer

2021-06-15CB11-065-120-160 Elektrische Bandsäge Bandsäge (0,7 kW)

2020-06-13DP21-050 Pneumatischer Handbohrer

2020-06-13DB21-032/040/050/060/070/100 Schwere pneumatische Ausgleichsbohrmaschine

2020-11-24RH31-1000/1250/1350/1400/1550/1800/2100 Hydraulischer Meißelhammer

2020-06-13AN22-4500/6000/10000 Pneumatische Drehmomentschlüssel

2021-06-03LW21-005 Pneumatische Winde

2021-06-16OF27-100/200/270/360/650/950 Tragbarer Gasverdünnungsventilator (Eisenlegierung)

2020-06-13DP61-090/100 Handbohrer mit Emulsion

2021-06-15CR21-001 Leichte pneumatische Säbelsäge

2021-06-07AW22-3000 Pneumatischer Schlagschrauber (Super Light Series)

2021-06-15CB22-120 160 200 Pneumatische Bandsäge - Edelstahl-Serie

2020-06-13DM21-023 Pneumatischer Magnetbohrer

2021-06-15RH21-1800 Pneumatischer Brechhammer

2021-06-16GG21-230 Pneumatischer Winkelschleifer

2021-06-15Zubeh?r

Bohrer aus Legierung

2020-06-13Zubehör für Schienenbohrer

2020-06-13pneumatische-balance-bohrer-9

2020-06-13Wasserpumpe

2020-06-13Pneumatischer HEBEZUG

2020-06-13Twist-Bit

2020-06-13Hydraulische Kettensäge-4-1

2020-06-13Diamant-Sägeblätter

2020-06-13Kettensägenzubehör-02

2020-06-13Kettensägenzubehör-01

2020-06-13Zubehör für pneumatische Kettensägen-03

2020-06-13Pneumatischer HEBEZUG

2020-06-13Feste Klemmen

2020-06-13pneumatische-balance-bohrmaschine-8

2020-06-13Feste Klemmen

2020-06-13pneumatische-balance-bohrer-7

2020-06-13pneumatische-wuchtbohrmaschine-6

2020-06-13pneumatische-wuchtbohrmaschine-6

2020-06-13Pneumatischer HEBEZUG

2020-06-13Diamantkreissägeblätter

2020-06-13Hydraulische Kettensäge-3

2020-06-13betonhydraulisch

2020-06-13pneumatische-balance-bohrer-9

2020-06-13Sägeblatt aus Legierung

2020-06-13Klemmen

2020-06-13Feste Klemmen

2020-06-13Hydraulische Kettensäge-5

2020-06-13Hydraulische Kettensäge-6

2020-06-13pneumatische-balance-bohrer-7

2020-06-13Kreissägeblätter aus Legierung

2020-06-13

Du bist hier: >

Du bist hier: >